| Market Overview

Nowadays, with the continuous improvement of living standards, people have higher expectations for the quality, health and convenience of drinking water. Traditional methods of boiling water in a kettle and standard room temperature direct drinking water purifiers are no longer sufficient to meet the demands of high-end consumers. As a result, the criteria for choosing water dispensers have become increasingly strict.

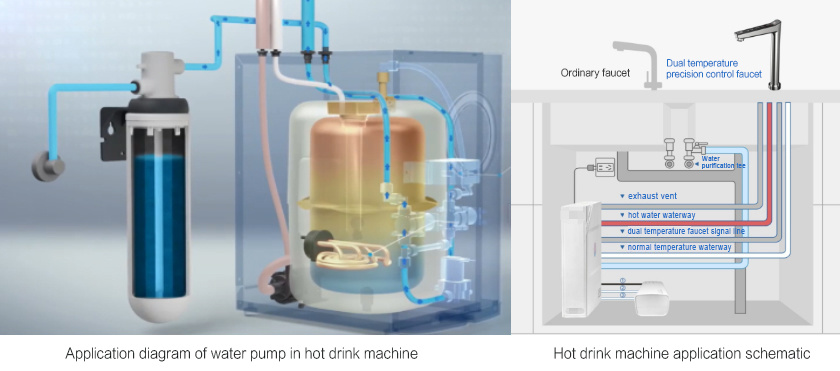

In this context, the under-counter boiling and chilled filtered dispenser has emerged. It incorporates a vacuum thermal chamber that can heat purified water, ensuring the safety and hygiene of drinking water. After purifying the water, it is heated and then maintained at a constant temperature within the vacuum thermal chamber. Additionally, it features a high-end intelligent temperature control system that can automatically adjust the water temperature to meet various needs. Whether for drinking, cooking, or cleaning, it is versatile and highly appreciated by consumers.

| Market Pain Points

However, the under counter boiling and chilled filtered water system still faces several pain points in high-temperature environments:

Plastic Material Issues: Plastics are susceptible to deformation at high temperatures, posing a threat to the product’s stability and lifespan.

Component Failures: In high-temperature environments, certain components may fail or even burn out, leading to the product’s inability to function properly.

High-Temperature Cavitation/Air Entrapment: Under high temperatures, the water pump may experience cavitation or air entrainment, causing a decrease in flow rate or even a complete stoppage of water flow, which clearly does not meet user expectations.

Odor Problems: Sometimes, water pump operation may be accompanied by odors, violating food-grade requirements and potentially posing health risks to users.

Speed Control Issues: In high-temperature environments, the speed control operation of the water pump may be unstable, affecting the product’s performance.

| TOPSFLO solutions

To address these customer pain points, TOPSFLO offers a range of innovative solutions:

Optimized material selection: Utilize high-temperature food-grade PPS plastic from South Korea, eliminating the use of mixed materials and recycled materials, ensuring that the product remains crack-free and deformation-free during long-term high-temperature use.

High temperature electronic components: Use electronic components designed to withstand high temperatures for extended periods. These components come from top international brands such as Samsung, Yageo, Melexis, DT, ST, and others. This ensures stability and reliability for long-term high-temperature use under extreme conditions.

High-Temperature Ventilation Design: Introduce a unique patented high-temperature exhaust rotor, effectively addressing cavitation issues and ensuring stable flow output at different temperatures without noise amplification or flow instability.

Food grade certification and odor evaluation: All products meet food-grade certifications and undergo rigorous odor assessments to ensure they have no odors in the high-temperature drinking industry, meeting users’ expectations.

Intelligent control: We provide professional integrated solutions to achieve intelligent control of the under-sink boiling and chilled filtered water system, such as PWM/5V speed regulation, FG signal feedback and more, enhancing the product’s intelligence .

Through these solutions, we help our customers overcome various challenges in high-temperature environments, ensuring product reliability, performance, and customer satisfaction.

TOPSFLO has a professional engineering team with 20 years of experience in the pump industry. After on-the-spot investigation of market demand and installation and matching tests of various electric water heater equipment, TOPSFLO has tailored a high-efficiency, low-noise brushless DC booster pump TL-C01 for the electric water heater industry:

| Basic Market Conditions Fossil fuels such as gasoline, diesel, LPG, coal and natural gas power much of the modern wo…

In a heat exchanger tank,how does the hot water at the bottom mix with the cold water in the upper part of the tank at the required time and rate to achieve a steady supply of warm water in the home?

With the improvement of people's living standards and spending power, and the popularization of the application of smart technology in home life, the application of smart toilets has gradually expanded to individual families.

The working principle of the water heated mattress pad is that the water is heated by the water storage device and then delivered to the water heated mattress pad by the brushless DC circulating water pump for heating